The use of natural refrigerant gases such as R290 and R600a in the refrigeration sector is key to reducing harmful substances emitted into the atmosphere and lowering the global greenhouse effect. At Rightway Asia, we have been pioneers in adapting our wide range of products to this new generation of refrigerants even before the F-Gas regulation came into place in 2016.

In fact, the company decided to start its journey towards natural refrigerant gases as soon as we saw the implementation of domestic refrigerators regulation, which came into force on 1 January 2015. Therefore, by the end of 2014 more than 95% of our refrigeration products were functioning with natural refrigerant gases R290 and R404.

Being sustainable is another way we can add value to products for our partners. Let’s learn more about the use of natural refrigerants in the refrigeration sector, which ones they are replacing and why.

The F-Gas Regulation and the hospitality sector

The European Regulation 517/2014 or F-Regulation on fluorinated greenhouse gases aims to reduce the emission of gases with a high Global Warming Potential (GWP). The goal is to cut by two-thirds the emission of these gases compared with 2014 levels.

The F-Gas regulation has a phase-out schedule for the use of refrigerants, in which the quotas for HFC marketing, established in the aforementioned regulation, are set and the use of alternative refrigerants that can replace HFCs with a high Global Warming Potential (GWP) is promoted. The Global Warming Potential (GWP) refers to a factor that measures how much more harmful the refrigerant is compared to CO2 (if released to the atmosphere).

Two of the most used HFC in the hospitality sector were R404A and R134A, but both of them are forbidden to be sold nowadays. R404A, with a GWP of 3922, cannot be sold since January 2020, and R134A, with a GWP of 1430, is forbidden since January 2022.

In view of their disappearance, although there is no deadline for service and maintenance of installed equipment, it is vital to have substitutes adapted to the legislation: such as those that work with R290 and R600a refrigerant gas.

In addition, the replacement of this type of refrigeration equipment allows us to opt for more efficient units with lower energy consumption, thanks to new technologies such as cutting-edge inverter compressors Therefore, the long-term energy savings will compensate for the investment in new equipment.

These non-fluorinated refrigerants also called “natural refrigerants”, have the advantage of no application deadline in the F-Gas regulation. Let’s get to know them a little better.

(R600A) Isobutane

With a very low GWP value of only 3, it is a huge improvement in terms of environmental impact. As a result, it has become one of the most popular refrigerants used today for domestic, commercial and industrial refrigeration.

R600a refrigerant is widely used in refrigerators in Europe, such as the models in our range of display cabinets.

Repair and maintenance of a system with R600a requires well-qualified and trained personnel and equipment. Due to the flammability of the gas, which is a potential risk during work on the refrigeration system, careful handling is necessary. Good ventilation of the room is necessary, and the unloading of the vacuum pump must be done in the open air. The service equipment must meet the requirements of R600a in terms of evacuation quality and precision in refrigerant charging.

R290, propane

R290 refrigerant, also known as propane, is a combination of isobutane and propane. Inexpensive and readily available, it is emerging as one of the most widely used refrigerants in commercial and industrial refrigeration.

It has a zero-ozone depletion potential (ODP) and a very low global warming potential. As a petroleum derivative, it is also considered a mineral refrigerant.

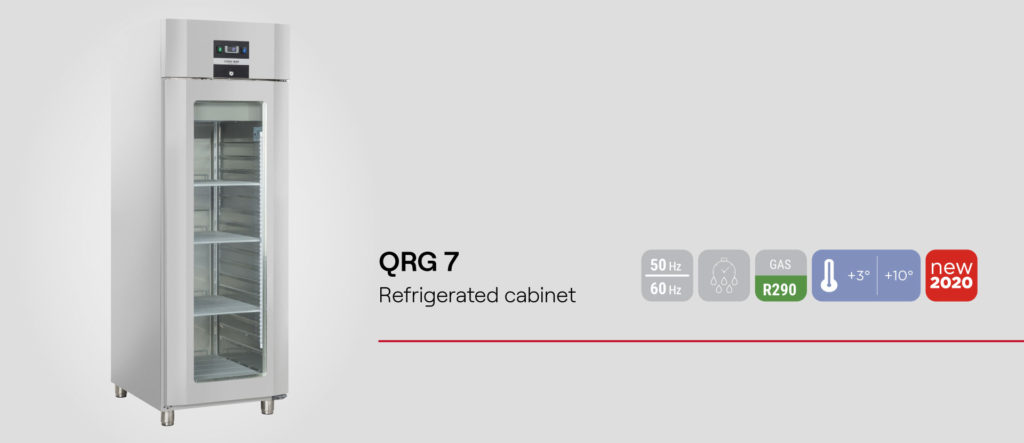

It is used in smaller displacement compressors, which means it can achieve a cooling capacity equivalent to that of R134a and R124yf gases, resulting in increased efficiency of commercial refrigeration equipment.

Given the above benefits, it is no surprise that they are increasingly employed as a more economical and environmentally friendly alternative, as well as an option that allows for significant advances in system design and efficiency within the refrigeration industry. Propane, however, must also be treated with care due to its flammability as discussed above.

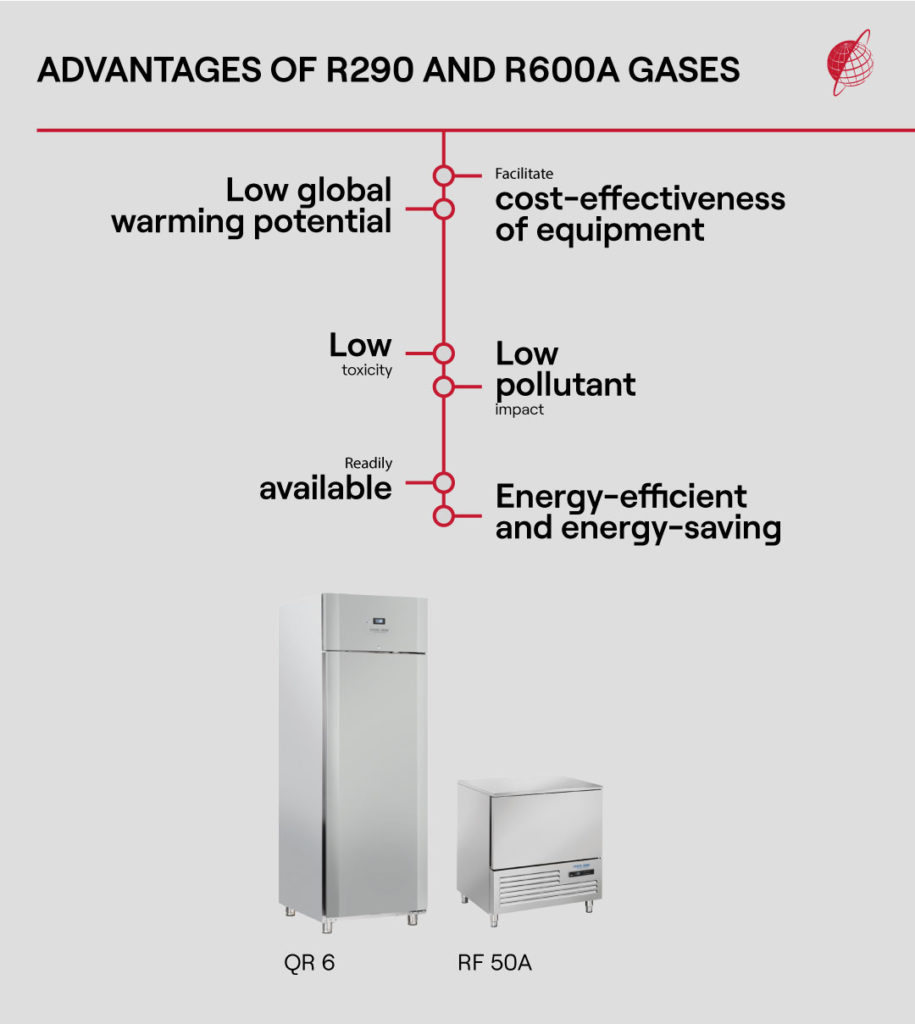

Advantages of R290 and R600A gases

A bit of History: the Kigali Amendment

The Kigali Amendment, which entered into force on 1 January 2019 and was adopted in Kigali on 15 October 2016, is the inclusion of hydrofluorocarbons, potent greenhouse gases used in refrigeration and air conditioning, in the scope of the Montreal Protocol, which entered into force on 1 January 1989.

By setting a timetable for reducing the consumption and production of hydrofluorocarbons, the Kigali Amendment should prevent the emission of about 72 billion tonnes of CO2 equivalent by 2050 and a temperature increase due to hydrofluorocarbons of about 0.5 °C by 2100.